Our field of expertise

Propulsion overhaul

From conventional to hybrid

Saltwater was commissioned to carry out the basic engineering for the conversion of two geotechnical survey vessels. The project focused on modernizing the vessels’ propulsion systems by replacing the conventional propellor shafts and stern tunnel thrusters with Azimuth thrusters. Additionally, a battery system was integrated to enable hybrid diesel-electric propulsion, enhancing operational efficiency and sustainability. The engineering work was based on an existing concept design, which Saltwater further developed and refined.

Through this conversion project, Saltwater successfully delivered a comprehensive engineering solution, supporting their client in the modernization of its fleet with an advanced and efficient hybrid propulsion system.

Naval architecture considerations

The conversion resulted in modifications to the hull shape, necessitating various naval architecture assessments, including:

- Updates to the vessel’s lines plan to accommodate the new propulsion system.

- Intact and damage stability analyses.

- Dynamic Positioning Analysis.

- Resistance and Propulsion predictions.

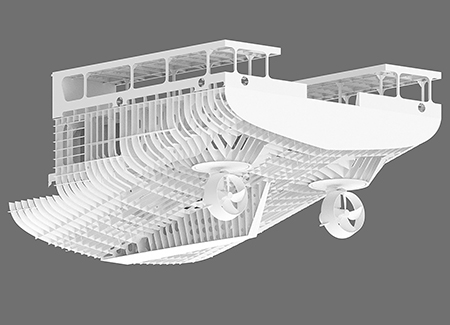

Structural modifications

To accommodate the new Azimuth thrusters, modifications to the vessel’s structural hull were required. The scope of work included:

- Designing and integrating new foundations for the propulsion units.

- Evaluating optimal installation methods within the vessel’s structural layout.

- Conducting structural assessments to verify the feasibility of the design.

Engineering

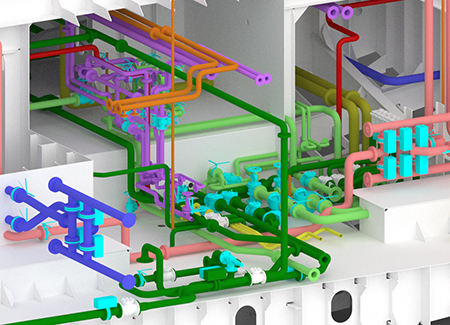

Detailed engineering and construction plans were developed, covering:

- 3D modeling and detailed design using Ship Constructor software for construction, piping, and electrical systems.

- Development of routing for the piping and elaborate them into spool pieces.

- Development electrical routing layouts.

System integration

The mechanical engineering scope included:

- Determining cable and piping routes to support the overall engineering process.

- Using 3D scans of the vessel to ensure accurate placement of piping and mechanical components.